Manufacturers face growing pressure to stand out in a crowded, price-sensitive market. With more customer options, tighter margins, and increasingly complex buyer expectations, selling has become harder—and more important—than ever. And with US manufacturers generating nearly $600 billion in sales every month, the stakes have never been higher. Sales teams need to go beyond traditional tactics by demonstrating a clear understanding of customer needs and how their company’s products address them. This approach builds trust, strengthens customer relationships, and helps manufacturers preserve profitability and increase revenue, even in the most competitive environments.

What Is a Manufacturing Sales Strategy?

A manufacturing sales strategy is a plan for how a manufacturer connects with customers and closes deals. Key components of a successful sales strategy include defining ideal customer profiles, aligning sales with marketing and product development, and streamlining go-to-market (GTM) efforts.

Key Takeaways

- Sales in manufacturing come with unique challenges, including complex product offerings, long sales cycles, and pressure to maintain attractive pricing.

- Manufacturers need a strategic sales approach to overcome these challenges, with a particular focus on cross-team alignment and the use of technology to improve operations.

- Personalized support and a deep understanding of customer needs are essential to winning and retaining business in competitive manufacturing industries.

Sales Strategy in Manufacturing Explained

Sales in manufacturing entail acquiring raw materials and components, assembling them into products, and bringing those products to market. Compared to other industries, sales in manufacturing require a deeper understanding of complex supply chains, technical specifications, and long-term customer relationships. This is because manufacturing involves highly specialized products, strict compliance standards, and lengthy sales cycles with multiple decision-makers. Manufacturers also face unique sales risks, such as commoditization and rapid changes in demand.

Sales strategies help manufacturers address these challenges by generating brand awareness, building audience trust, and accelerating time to close. Outbound sales techniques, including cold-calling, are common components of these strategies, but inbound approaches, such as content marketing, are increasingly important as more business is conducted online. Sales enablement plays a critical role by equipping teams with customer relationship management (CRM) systems and other resources to improve customer engagement. Automation and ecommerce platforms, meanwhile, further optimize sales processes.

Manufacturers are also turning to artificial intelligence (AI), Internet of Things devices (IoT), and analytics to execute sales strategies more efficiently and open up new revenue streams, such as subscription services for equipment monitoring and predictive maintenance. Data-driven tools and flexible, scalable systems will be key to addressing supply chain disruptions, cost pressures, and evolving customer expectations.

Common Challenges in Manufacturing Sales

Manufacturers face distinctive sales challenges that can delay or halt deals and squeeze profit margins. The complexity of products creates longer sales cycles, affecting cash flow and exacerbating competitive pressure. And the constant threat of supply chain disruptions looms large. Here are some of the more common obstacles facing manufacturing businesses today:

- Complex product offerings: Technical intricacy and heavy product customization complicate manufacturing sales processes. Sales teams need in-depth product knowledge and must collaborate closely with their engineering, production, and research and development colleagues to develop tailored proposals that meet customer needs. Maintaining engagement with various stakeholders is crucial to avoid misunderstandings that can derail potential sales.

- Longer sales cycles: Product complexity typically leads to more decision-makers, prolonging sales cycles. For example, the sales force must develop rapport with multiple stakeholders, each with their own unique priorities, and negotiate detailed terms that address these disparate concerns. Additionally, most manufacturers have large product libraries, increasing the time it takes for customers to identify the exact offerings needed, which can also delay deals.

- Cost competition: As globalization and advancements in technology have made it easier for customers to find, evaluate, and buy from alternative suppliers, manufacturers face significant pressure to maintain attractive pricing and preserve profitability. The sheer number of competitors selling similar products forces manufacturers to differentiate their offerings and clearly communicate their value to justify prices. Changing market dynamics, such as raw material cost fluctuations, further complicate pricing, particularly in commoditized industries or when selling to large customers with significant bargaining power.

- Supply chain disruptions: Supply chain interruptions can cause production and delivery delays, raw materials shortages, or increased operational costs, any of which affect a manufacturer’s ability to make and sell products. These factors also impact inventory management, often resulting in stockouts (which negate immediate revenue opportunities and damage customer loyalty) or excess inventory (which ties up cash flow and adds expenses). Additionally, the costs of circumventing supply chain disruptions, such as to expedite shipping or source alternative materials, can erode profit margins and pricing advantages.

9 Strategies to Increase Manufacturing Sales

To increase sales in light of these challenges, manufacturers must adopt a smarter, more strategic course. The most successful sellers regularly assess their tactics and strategies, while aligning their GTM efforts with common goals and implementing technology to increase efficiency. These nine strategies help manufacturers drive growth as they strive to improve the customer experience.

1. Audit Your Current Sales Strategies

Outdated systems and redundant processes hinder operations and make it harder for sales reps to close deals. Thoroughly evaluate all sales workflows and tools to pinpoint strengths, weaknesses, and areas for improvement, focusing on how well your team understands product specifications, customization options, and industry regulations. Analyze key performance indicators (KPIs), such as customer acquisition costs, conversion rates, and revenue by product line, to uncover inefficiencies and bottlenecks unique to manufacturing, including delays caused by long lead times or misaligned expectations between sales and production teams. A high drop-off rate after initial calls, for example, could indicate misalignment between marketing’s leads and the sales team’s ideal customers. Examine lead sources, qualification rates, and closing ratios with attention to distributor relationships, OEM partnerships, and project-based sales cycles to discover where prospects exit the sales funnel. Then address the root causes at those specific stages to improve alignment and close rates.

Additionally, document all audit findings in a detailed report and provide actionable recommendations—optimize sales collateral or automate prospect outreach, for instance—to increase efficiency, enhance customer engagement, and grow revenue. Conduct these audits regularly to ensure continuous improvement and awareness of changing market conditions.

2. Align Sales, Marketing, and Product Teams

Misalignment among sales, marketing, and product teams can result in wasted efforts, such as sales teams struggling to close deals because of inconsistent messaging. To avoid such scenarios, encourage open communication, set shared goals, and integrate technology across teams. For manufacturers specifically, this means making sure sales teams thoroughly understand production capabilities, lead times, and customization options to set realistic customer expectations. For example, holding regular meetings and sharing data between sales and marketing teams will fuel collaboration and feedback, enabling deeper customer insights, better-targeted campaigns, enhanced outreach, and improved sales strategies. Similarly, cross-functional factory tours and production-floor visits can help marketing teams create more accurate materials that highlight genuine manufacturing differentiators, rather than generic benefits.

A unified tech stack, such as a CRM system, fosters real-time collaboration to help teams track lead progress and respond quickly to market changes. Integration with enterprise resource planning (ERP) and manufacturing execution systems gives sales teams visibility into production schedules and inventory levels, allowing them to provide customers with accurate delivery timelines while reducing order fulfillment issues.

3. Understand Your Market

Effective manufacturing sales require a comprehensive understanding of ideal customer profiles, pain points, and purchasing processes. Develop and regularly update channel strategies, personas, and research materials to remain competitive and sync with evolving customer needs. Here’s how.

- Analyze channel strategies: Engage prospects with an omnichannel approach, complementing in-person meetings and other traditional methods with digital-first strategies, such as targeted email campaigns, social selling on LinkedIn, webinars, and content marketing.

- Develop buyer personas: Develop detailed personas that outline demographics, job roles, buying behaviors, and pain points. A procurement manager focused on cost reduction, for example, will respond differently to messaging than an engineer interested in technical specifications.

- Keep a pulse on market trends: Staying up to date on buyer preferences and emerging trends facilitates proactive adjustments to product offerings and sales strategies. Conduct competitor analyses, customer interviews, and industry research to identify market trends and customer preferences.

4. Consider an Aftermarket Sales Strategy

A strong aftermarket strategy transforms manufacturers from vendors into long-term partners. Aftermarket sales of spare parts, along with upgrades, maintenance, and repair services, create recurring revenue opportunities, encourage customer loyalty, and increase profitability over the long term. These offerings also provide insights into how products perform under real-world conditions and what parts or components need improvement.

Identify products with high potential for aftermarket sales and services, such as equipment requiring frequent replacements or periodic tune-ups. Then establish a clear business model—direct to customer, through channel partners, or a hybrid approach—and use ecommerce and data analytics platforms to streamline both the buying process and internal operations. Online ordering for replacement parts and automated service reminders, for example, simplify purchasing for customers.

5. Improve Your Presence Online

A strong online presence extends a manufacturer’s reach and creates new sales opportunities. Businesses that neglect their web and social media presence limit their audience and may appear less credible than the competition. A proactive digital strategy also builds trust and enhances the buying experience, positioning manufacturers for greater sales success. Consider the following avenues to bolster your online presence:

- Corporate website: A website isn’t just a hub for company information or an online product catalog. It should serve as a sales tool that attracts and nurtures prospects, provides customer support, and lowers purchasing barriers through ecommerce capabilities. For example, a potential customer should be able to research technical specifications, view product demos, and request a quote, all without ever leaving the site.

- Social media: Consistent posting on social media increases brand visibility, while regular engagement opens up direct lines of communication with prospects and customers. Sharing content that demonstrates an understanding of audience pain points and highlights success stories enriches those relationships by cultivating loyalty and trust. Identify the platforms your target customers predominantly use and focus efforts there to maximize results.

- Search engine optimization (SEO): By ranking highly in online search results for targeted keyword phrases, manufacturers can attract qualified traffic to their websites. Proper keyword choice and usage are essential, but successful SEO strategies also involve creating valuable content, optimizing website structure, building high-quality backlinks, and ensuring mobile-friendliness.

- Review management: Positive reviews and testimonials significantly influence buying decisions. Manufacturers should take an active role by encouraging happy customers to leave reviews—on the company website, social media, and third-party review platforms—and by soliciting participation in more formal case studies. Manufacturers that actively manage and respond to reviews can further demonstrate their commitment to customer satisfaction.

- Digital storefronts: A well-designed storefront with interactive support and secure payment options allows manufacturers to better showcase products, facilitate sales, and augment the buying experience for online customers. Integration between a digital storefront and a CRM system brings additional improvements to sales processes and customer service, such as the ability to automatically update customer preferences after a new purchase.

6. Enable an Excellent Customer Experience

Manufacturers that prioritize the customer experience make the buying process easier, nurture loyal customers, and drive repeat business, making them more likely to reap increased sales. Build a strong customer support team to provide timely responses to technical questions and encourage self-serve support by offering access to frequently asked questions and other documentation. Additionally, establish a culture of customer success early on, beginning with the sales process itself. Ensure that leads know how to reach their appropriate contacts when needed and that they respond promptly to all inquiries. Provide product catalogs, comparison tables, and other materials to aid customer decision-making. Consistently delivering positive experiences allows manufacturers to differentiate themselves, build lasting relationships, and sustain revenue growth.

7. Strengthen Your Value Proposition

A clearly articulated value proposition makes it easy for buyers to see a product’s unique advantages, positioning the manufacturer as the preferred choice in a competitive market. Tailor sales pitches to highlight specific benefits that match each prospect’s goals, and demonstrate how certain products and features address their unique needs. When selling machinery to a sustainability-focused buyer, for example, emphasize the product’s energy efficiency, long-term cost savings, and compliance with environmental regulations.

Use informational collateral, including case studies and testimonials from similar customers, to showcase proven results and make pitches more credible. Anticipate customer objections, such as concerns about up-front costs or implementation timelines, and prepare clear, data-backed answers to proactively address them. Finally, personalize sales messaging to build stronger connections with prospects and close deals more effectively.

8. Automate Manual Tasks

Manufacturers that ignore automation risk falling behind competitors and missing out on opportunities to optimize sales processes and accelerate revenue growth. Automate time-consuming manual tasks, such as data entry, lead scoring, and prospect outreach, using workflows that facilitate timely follow-ups and effective lead nurturing. Website visitor details, captured through a lead generation form, for instance, can launch personalized email sequences based on user behavior and interests.

Automation tools that integrate with CRM, inventory management, and scheduling systems bring additional benefits that allow the sales team to focus on higher-value tasks, significantly increasing productivity. A sales quote automation tool, for example, can import CRM data, saving reps hours per week. Business process automation (BPA) goes even further, by streamlining complete workflows, such as order processing, invoicing, and inventory updates, across multiple departments.

9. Invest in a CRM Solution

Without a CRM system to collect leads, automate processes, and track sales performance, manufacturers may struggle to effectively manage pipelines and discover growth opportunities. CRM systems give manufacturers the tools they need to measure results against internal KPIs and industry benchmarks, analyze sales data to identify strengths and weaknesses, and assess the effectiveness of marketing campaigns. CRM features, such as lead capture and scoring, profile enrichment, omnichannel communication, and data-driven reporting, are essential for achieving those goals.

NetSuite for Manufacturing Combines ERP and CRM

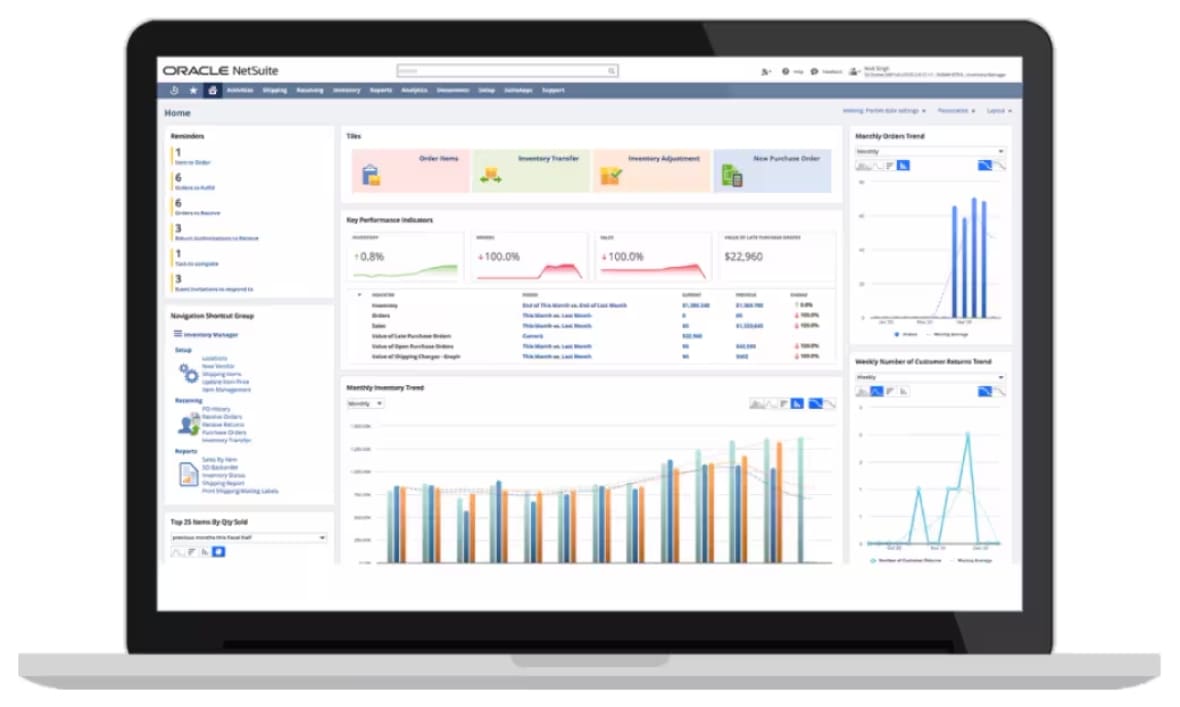

Manufacturers often struggle with disconnected sales systems that hinder collaboration and limit visibility. Successfully aligning sales, marketing, and product teams requires availability of shared data and streamlined workflows. And the ability to personalize sales pitches, offer rapid customer support, and proactively address market trends hinges on having immediate access to accurate customer and product data.

NetSuite’s manufacturing ERP solution addresses these issues by natively integrating CRM functionality with comprehensive business management capabilities. By unifying data across sales, marketing, product development, and customer service departments, NetSuite delivers a 360-degree view of each customer, allowing sales teams to tailor their approach, anticipate needs, and provide exceptional support. The unified platform also supports BPA to help manufacturers optimize operations, reduce errors, and accelerate response times, ultimately increasing sales and strengthening customer relationships.

Track Manufacturing KPIs With NetSuite ERP

Manufacturing sales teams face complex, evolving challenges, but they can drive consistent growth with the right strategies. As digital channels become more prevalent and customer expectations continue to shift, success will depend on how quickly companies adapt. The future belongs to manufacturers whose sales strategies embrace data, encourage collaboration across departments, and foster agility.

#1 CRM

In The Cloud

Manufacturing Sales Strategy FAQs

What is the role of marketing in the manufacturing industry?

The role of marketing in the manufacturing industry is to create brand awareness, generate and nurture leads, and collaborate with sales and product teams on messaging and positioning to create demand for specialized products.

How do I choose a sales methodology?

Choose a sales methodology for your manufacturing company by analyzing your products, sales cycle, customer needs, and team strengths. Select a methodology that aligns with business goals and your customers’ preferred buying habits to facilitate a mutually beneficial sales process.

How do I improve my manufacturing sales process?

Improve your manufacturing sales process by auditing existing strategies; aligning sales, marketing, and product teams; conducting ongoing market research; strengthening your online presence; and providing exceptional customer service.